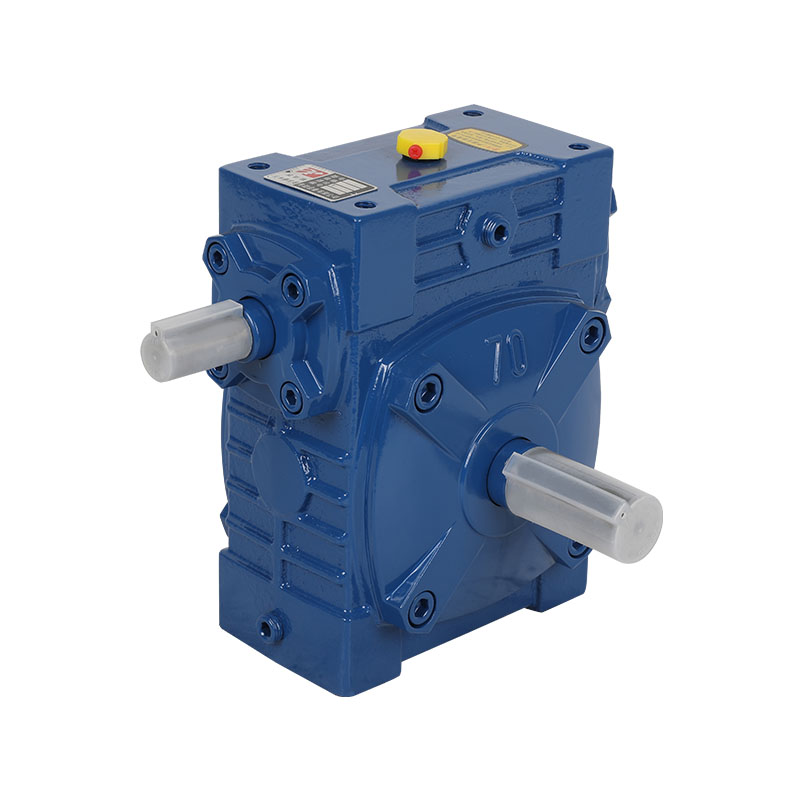

The load-bearing capacity and torque output of WP worm gear reducers are important aspects of their performance and are directly related to the performance of the reducer in practical applications. The following is a detailed analysis of the load-bearing capacity and torque output of WP worm gear reducers:

Load-bearing capacity

WP worm gear reducers are known for their high load-bearing capacity and are particularly suitable for heavy-duty working environments. Their load-bearing capacity mainly depends on the following aspects:

Material and structure: The worm is usually made of high-quality steel and is heat-treated to improve hardness and wear resistance.

The worm wheel is often cast with wear-resistant materials such as tin bronze and has good wear resistance.

The housing structure is usually designed to be strong and durable and able to withstand large torques and loads.

Design and manufacturing process: The design and manufacturing process of the reducer have an important influence on its load-bearing capacity. High-precision processing and optimized structural design can improve the load-bearing capacity and operating stability of the reducer.

Use environment: The use environment of the reducer will also affect its load-bearing capacity. When used in harsh environments, appropriate protective measures need to be taken to ensure the normal operation and load-bearing capacity of the reducer.

Torque output

WP worm gear reducer can achieve higher torque output through the meshing transmission of worm wheel and worm. Its torque output characteristics mainly depend on the following aspects:

Reduction ratio: The larger the reduction ratio, the larger the output torque. By adjusting the reduction ratio, the torque output requirements of different applications can be met.

Input torque: The input torque is the basis of the torque output of the reducer. When the input torque is constant, the design of the reducer determines the maximum torque it can output.

Transmission efficiency: The higher the transmission efficiency, the smaller the torque loss, so that a greater output torque can be obtained. WP worm gear reducer strives to improve transmission efficiency to increase torque output by optimizing design and using high-quality materials.

Specific performance

Specific to different models and specifications of WP worm gear reducers, their load capacity and torque output will be different. Generally speaking, the maximum load capacity and maximum torque output values of the reducer will be clearly marked in the technical specification table of the reducer. For example, some models of WP worm gear reducers may have a maximum torque output capacity of up to hundreds of Newton meters, which can meet the needs of various heavy-duty applications.

In summary, WP worm gear reducers are widely used in the field of mechanical transmission due to their high load-bearing capacity and good torque output characteristics. Their load-bearing capacity and torque output are affected by many factors such as materials, structure, design, manufacturing process and use environment. When selecting and using WP worm gear reducers, it is necessary to select appropriate models and specifications according to specific application requirements and conditions to ensure the stability and reliability of their performance.

English

English русский

русский bahasa Indonesia

bahasa Indonesia